Table of Contents

Advertisement

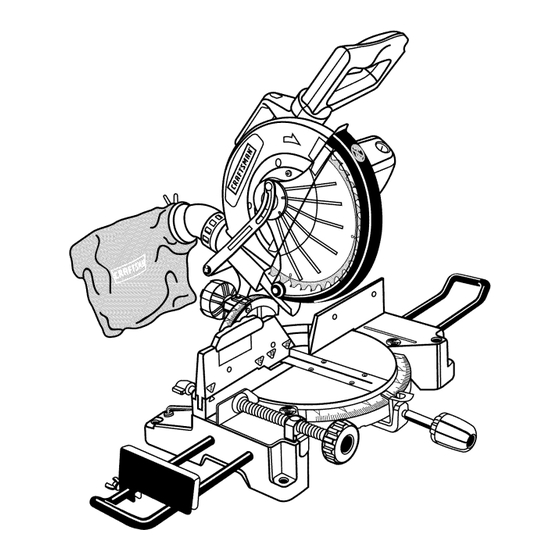

OPERATOR'S

MANUAL

II:RRFTSMRN I

10 in. COMPOUND

MITER SAW

DOUBLE INSULATED

Model Nos.

315.212340

_

WARNING:

To reduce the risk of injury,

the user must read and understand the

operator's manual before using this product.

Customer

Help Line: t-800-932-3188

Sears, Roebuck

and Co., 3333 Beverly Rd., Hoffman

Estates, IL 60179 USA

Visit the Craftsman web page: www.sears.com/craftsman

983000-517

9-04

Save this manual for future reference

Advertisement

Table of Contents

Summary of Contents for Craftsman 315.212340

- Page 1 Customer Help Line: t-800-932-3188 Sears, Roebuck and Co., 3333 Beverly Rd., Hoffman Estates, IL 60179 USA Visit the Craftsman web page: www.sears.com/craftsman Save this manual for future reference 983000-517 9-04...

-

Page 2: Table Of Contents

Back Page ONE YEAR FULL WARRANTY ON CRAFTSMAN TOOL If this Craftsman tool fails due to a defect in material or workmanship within one year from the date of purchase, CONTACT THE NEAREST SEARS PARTS & REPAIR CENTER at 1-800-4-MY-HOME ®... - Page 3 • SECURE WORK. Use clamps or a vise to hold work WARNING: Read and understand all instruc- tions. Failure to follow all instructions listed below, when practical. It's safer than using your hand and may result in electric shock, fire and/or serious frees both hands to operate tool.

- Page 4 • INSPECT TOOL CORDS PERIODICALLY. If damaged, • USE ONLY CORRECT BLADES. Do not use blades haverepaired bya qualified service technician at with incorrect size holes. Never use blade washers or anauthorized s ervice facility. T heconductor w ith blade bolts that are defective or incorrect. The maxi- insulation h aving anoutersurface thatisgreen with mum blade capacity of your saw is 10 in.

- Page 5 • NEVER handholda workpiece thatistoo small t o be • STAY ALERT! Do not allow familiarity (gained ALWAYS clamped. K eephands clearof thecuttingarea. from frequent use of your saw) to cause a careless mistake. ALWAYS REMEMBER that a careless fraction •...

-

Page 6: Symbols

Someofthefollowing symbols maybeusedonthistool.Please studythemandlearn theirmeaning. Proper interpretation ofthesesymbols willallowyouto operate thetoolbetterandsafer. SYM BOL NAM E DESIG NATION/EXPLANATION Volts Voltage Amperes Current Hertz Frequency ( cycles persecond) Watt Power Minutes Time "%, Alternating Current Type of current Direct Current Type or a characteristic of current No Load Speed Rotational speed, at no load... - Page 7 Thefollowing signal w ordsandmeanings a reintended to explain the levels ofriskassociated withthis product. SYMBOL SIGNAL MEANING Indicates an imminently hazardous situation, which, if not avoided, will DANGER: result in death or serious injury. Indicates a potentially hazardous situation, which, if not avoided, could WARNING: result in death or serious injury.

-

Page 8: Electrical

DOUBLE INSULATION EXTENSION CORDS Double insulation is a concept in safety in electric power When using a power tool at a considerable distance from tools, which eliminates the need for the usual three-wire a power source, be sure to use an extension cord that has grounded power cord. - Page 9 Anti-Kickback Pawls (radial arm and table saws) Non-Through Cuts A devise which, when properly installed and maintained, Any cutting operation where the blade does not extend is designed to stop the workpiece from being kicked back completely through the thickness of the workpiece. toward the front of the saw during a ripping operation.

- Page 10 PRODUCT SPECIFICATIONS Blade Diameter ......10 in. Cutting Capacity with Miter at O°/Bevel 0°: Maximum nominal lumber sizes: ....2 x 6, 4 x 4 Blade Arbor ....... 5/8 in. Cutting Capacity with Miter at 45°/Bevel 0°: No Load Speed ......5,000/min.

-

Page 11: Features

KNOW YOUR COMPOUND MITER SAW SPINDLE LOCK BUTTON See Figure 1. See Figure 3. Before attempting to use this product, familiarize yourself A spindle lock button has been provided for locking the with all operating features and safety rules. spindle which keeps the blade in your saw from rotating. Depress and hold the lock button while installing, chang- 15 AMP MOTOR ing, or removing blade. - Page 12 ROTATING HANDLE POSITIVE STOPS ON MITER TABLE See Figure 5. Positive stops have been provided at 0 °, 15°, 22-1/2 °, 30 °, and 45 ° on both the left and right side of the miter table. The rotating handle can be adjusted to provide different positions of the saw handle.

- Page 13 Thefollowing tools(notincluded) areneeded forchecking adjustments o fyoursaworforinstalling theblade: COMBINATION WRENCH(2) 10 ram,14 mm COMBINATION SQUARE FRAMINGSQUARE PHILLIPSSCREWDRIVER Fig. 6...

- Page 14 Thefollowing itemsareincluded withyourCompound M iterSaw: • DustBag • WorkClamp • DustGuide • Blade Wrench • OuterBlade Washer • Table Extensions ( 2) • Bolt • Clamp Brackets (2) • HexKey(2),8 mmand6 mm • Clamp Bracket S crews (2) • Operator's M anual •...

-

Page 15: Assembly

WARNING: Do not attempt to modify this tool UNPACKING or create accessories not recommended for use This product requires assembly. with this tool. Any such alteration or modification • Carefully lift saw from the carton by the carrying handle misuse and could result in a hazardous condition and the saw base, and place it on a level work surface. - Page 16 Asmentioned previously, thesawhasbeen factory assembled a ndadjusted. Themiterlockhandle, d ust guide, a ndbladearetheonlypartsthathaveto be installed. EXHAUST MITER LOCK HANDLE PORT See Figure 9. Cut the tie-wraps holding the saw arm and the miter lock in place. To install the miter lock handle, place the thread- ed stud into the threaded hole in the control arm.

- Page 17 TABLE EXTENSIONS See Figures 12- 13. If you plan to use the stop block, slide the stop block on the back arm of the desired table extension first. TABLE To install table extensions, insert the ends of extensions EXTENSION into the holes in the sides of the base. Adjust the exten- sions to the desired length.

-

Page 18: Operation

WORK CLAMP TO INSTALL BLADE See Figure 14. See Figures 15 - 17. The work clamp provides greater control by clamping the WARNING: A 10 in. blade is the maximum blade workpiece to the fence or the saw table. It also prevents capacity of the saw. - Page 19 LOWER WARNING: If inner blade washer has been BLADE GUARD removed, replace it before placing blade on PHILLIPS spindle. Failure to do so could cause an accident SCREW since blade will not tighten properly. • Fit saw blade inside lower blade guard and onto spindle.

- Page 20 MOUNTING THE LASER GUIDE ALIGNING THE LASER GUIDE LINE See Figure 18. See Figure 19. • Unplug the saw. The laser guide will generate a red colored line on the work surface when the blade is spinning above 500 rpm. See "To Install Blade"...

-

Page 21: Adjustments

NOTE: M anyoftheillustrations i nthismanual showonly FRAMING FENCE MITER TABLE portions ofthecompound mitersaw.Thisisintentional so SQUARE thatwecanclearly showpointsbeingmadeinthe illustrations. Neveroperateyoursawwithoutall guards securelyin placeandin goodoperatingcondition. SQUARING THE MITER TABLE TO THE FENCE See Figures 20 - 23. • Unplug the saw. • Push down on the saw arm and pull out the lock pin to release the saw arm. - Page 22 SQUARING THE SAW BLADE TO THE FENCE See Figures 24 - 27. FENCE BLADE • Unplug the saw. • Pull the saw arm all the way down and engage the lock pin to hold the saw arm in transport position. •...

- Page 23 SQUARING THE BLADE TO THE MITER TABLE See Figures 28 - 30. FENCE • Unplug the saw. • Pull the saw arm all the way down and engage the lock pin to hold the saw arm in transport position. • Loosen the miter lock handles.

- Page 24 Thissawhastwo scaleindicators, oneonthebevel s cale andoneonthemiterscale. A ftersquaring adjustments havebeenmade, i t maybenecessary to loosen the indi- FENCE catorscrewsandreset t hemto zero. COMBINATION SQUARE MITER TABLE VIEW OFBLADENOT SQUARE WITH MITER TABLE,ADJUSTMENTS AREREQUIRED Fig. 31 CUTTING WITH THE COMPOUND MITER WARNING: Do not allow familiarity with tools to make you careless.

- Page 25 TO MITER CUT • Rotate the saw table until the pointer aligns with zero on the miter scale. • Pull out the lock pin and lift saw arm to its full height. • Retighten the miter lock handles securely. • Loosen the miter lock handles.

- Page 26 • Grasp thesawhandle firmly thensqueeze theswitch WARNING: To avoid serious personal injury, always trigger. A llowseveral seconds forthebladeto reach tighten the miter lock handle securely before making maximum speed. a cut. Failure to do so could result in movement of the control arm or miter table while making a cut.

- Page 27 • Grasp the saw handle firmly then squeeze the switch trigger. Allow several seconds for the blade to reach maximum speed. • Slowly lower the blade into and through the workpiece. • Release the switch trigger and allow the blade to stop rotating before raising the blade out of workpiece.

- Page 28 CUTTING COMPOUND MITERS To aid in making the correct settings, the compound angle setting chart below has been provided. Since compound cuts are the most difficult to accurately obtain, trial cuts should be made in scrap material, and much thought and planning made, prior to making your required cut.

- Page 29 CUTTING CROWN MOLDING When setting the bevel and miter angles for compound miters, remember that the settings are interdependent; The compound miter saw does an excellent job of cut- changing one angle changes the other angle as well. ting crown molding. In general, compound miter saws do a better job of cutting crown molding than any other tool Keep in mind that the angles for crown moldings are very...

- Page 30 Bevel Angle Type of Cut Setting Left side, inside corner 1. Top edge of molding against fence 33.85 ° 2. Miter table set right 31.62 3. Save left end of cut Right side, inside corner 1. Bottom edge of molding against fence 33.85 °...

- Page 31 DEPTH STOP _i, WARNING:Before performing a nyadjustment, makesurethetool isunplugged f romthe power See Figure 43, supply andthe switchis inthe OFF ( O ) position. The depth stop limits the blade's downward travel. It Failure to heed this warning could result in serious allows the blade to go below the miter table enough to personal injury.

- Page 32 DEPTH STOP ADJUSTMENTS • Lower the blade into the miter table. Check blade clearance and maximum cutting distance (distance See Figure 43. from fence where blade enters) to front of miter table • Unplug the saw. slot. • To adjust the depth stop use a 10 mm wrench or •...

- Page 33 CHANGING THE BATTERIES See Figure 45. • Unplug the saw. LASERGUIDE Remove the laser guide from the saw. Lay laser guide on SUPPORT a flat surface with the two phillips screws facing upward. Remove the screws and separate the laser guide cover from the laser guide support.

- Page 34 _-_' CRAFTSMAN COMPOUND MITER SAW- MODEL NUMBER 315.212340 FIGURE A...

- Page 35 CRAFTSMAN COMPOUND MINTER SAW = MOOEL NUMBER 315.212340 dence regarding your Compound Miter Saw or when ordering repair parts. The model number wil! be found on a plate attached to the motor housing. Always mention the model number in al! correspon=...

- Page 36 _,__' CRAFTSMAN COMPOUND MINTER SAW- MODEL NUMBER 315.212340 FmGURE B SEE NOTE NOTE : The assembty shown represents an important part of the double insulated system. To avoid the possibility of alteration or damage to the sys- tem, service should be performed by your nearest Sears Repair Center. Contact your nearest Sears retail store for service center information.

- Page 37 CRAFTSMAN COMPOUND MITER SAW - MODEL NUMBER 315.212340 plate housing. Always correspondence The model number will be found attached to the motor mention the model number in all regarding your Compound Miter Saw or when ordering repair parts. PARTS UST - NGURE...

- Page 38 _,__' CRAFTSMAN COMPOUND MINTER SAW- MODEL NUMBER 315.212340 FmGURE C...

- Page 39 CRAFTSMAN COMPOUND MINTER SAW = MODEL NUMBER 315.212340 The modeJ number wiHbe found On a plate atiaChed i0 the motor housing. Always mention the mode, number in all correspondence regarding your ompound Miter Saw or when ordering repair parts. PARTS LmST - FmGURE C...

- Page 40 _,__' CRAFTSMAN COMPOUND IVimTERSAW- MODEL NUMBER 315.212340 "_ PARTS LmST - FIGURE...

- Page 41 CRAFTSMAN COMPOUND MINTER SAW- MODEL NUMBER 315.212340 The model number will be found on a plate attached to the motor housing. Always mention the model number in all correspondence regarding your 1 Compound Miter Saw or when ordering repair parts.

- Page 42 iii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!ii!i , ® Registered Trademark / TMTrademark Service Mark of Sears, Roebuck and Co. ® Marca Registrada Mama de F_brica Marca de Servicio de Sears, Roebuck Marque de commerce Marque d6pos6e de Sears, Roebuck and Co. ® Sears, Roebuck and Co.